- Products

- Manufacturing

Purpose-built Manufacturing ERP Software

Manufacturing Software Built for How You Actually Work

Generic software forces you to work around its limitations. Klipboard Manufacturing is different - built specifically for manufacturers who need manufacturing ERP software to manage complex Bills of Materials, track production through works orders, and maintain full traceability from raw materials to finished goods. Whether you're running a job shop or a high-volume production line, Klipboard gives you the control and visibility your operation demands.

How We Help You

Complete control over your manufacturing operation and inventory.

Real-time inventory control

Batch & serial traceability

Works order processing

Integrated costing & margins

Supplier & purchasing control

Production visibility & reporting

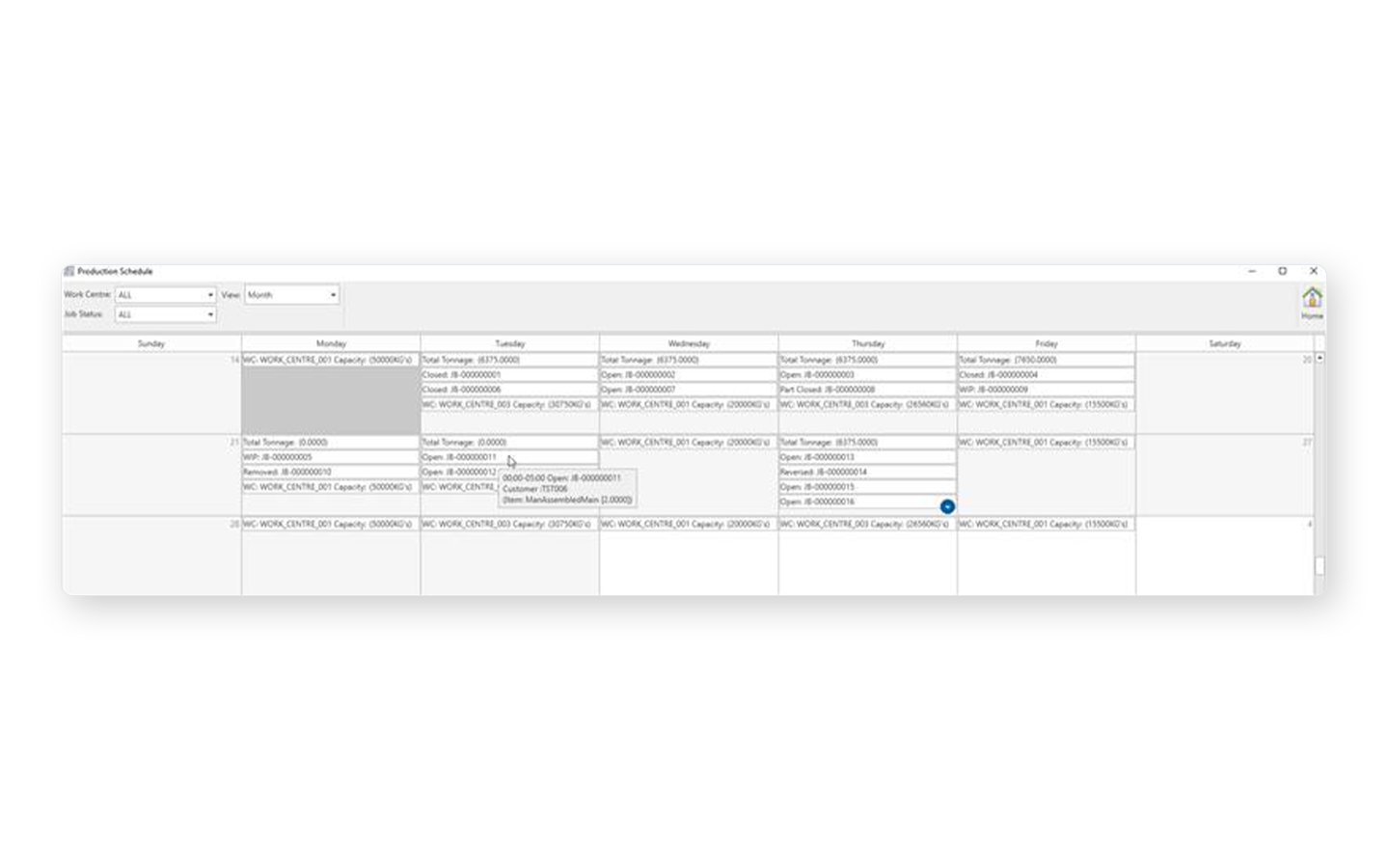

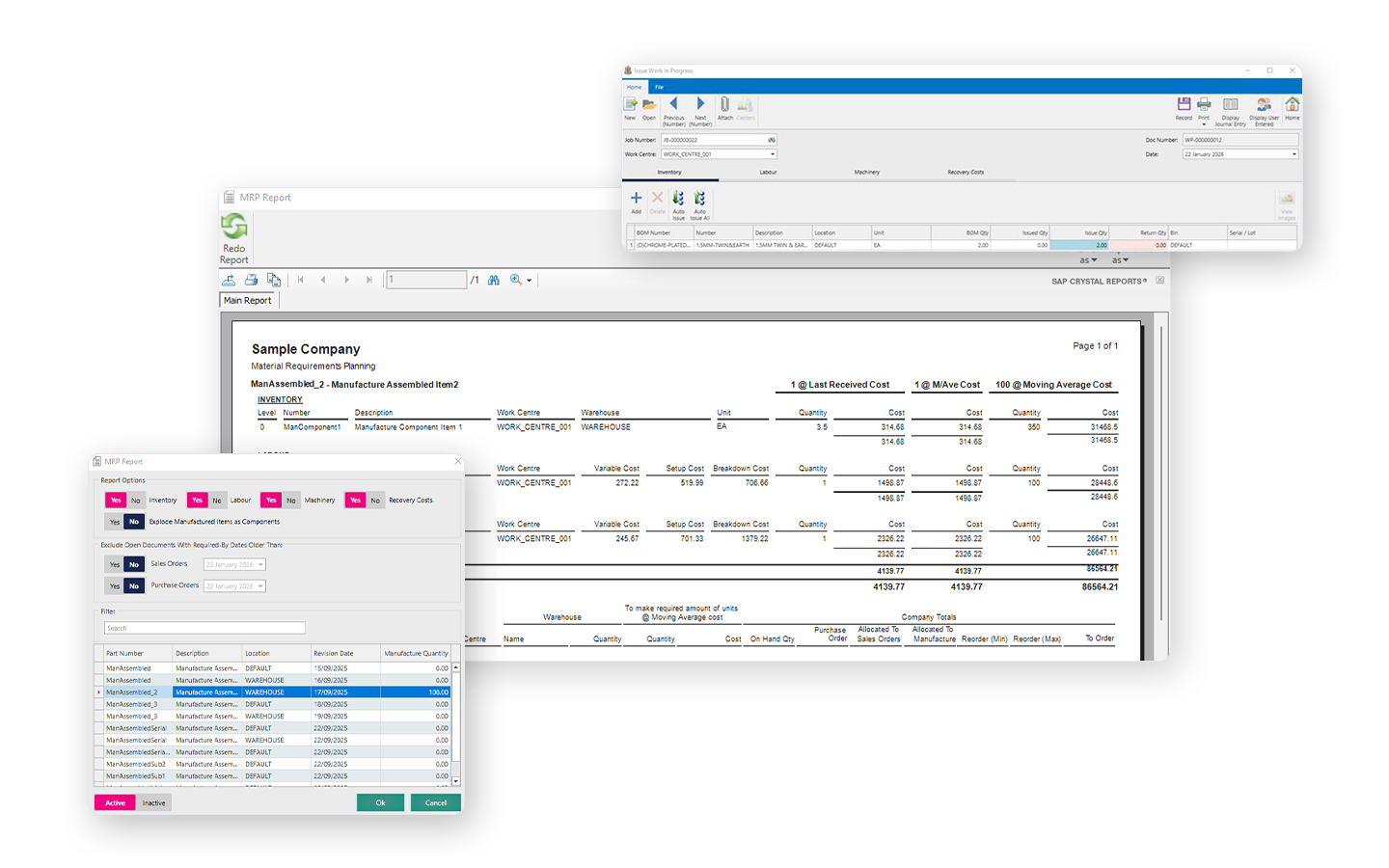

Material planning & scheduling

Multi-level BOM management

Warehouse & stock management

- Manufacturing, End-to-End

- Accurate Job Profitability

- Advanced BOM Management

- End-to-End Works Orders

- Built-In Batch Traceability

- Inventory That Keeps Moving

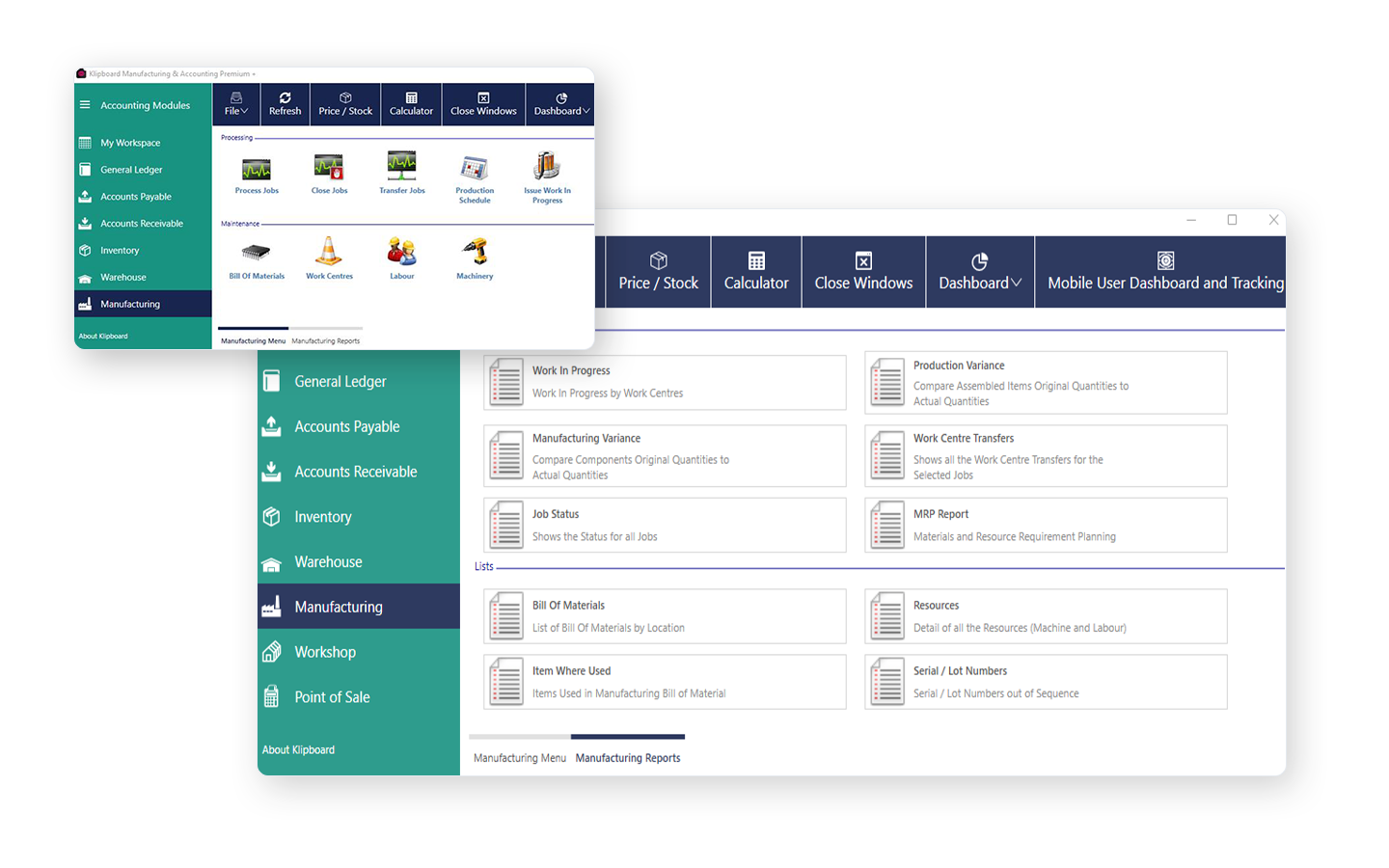

Manufacturing, End-to-End

From Raw Materials to Finished Goods - Under Control

Manufacturing operations live or die by their ability to coordinate materials, production, and delivery. Klipboard Manufacturing connects every stage of your operation using ERP software for the manufacturing industry, from purchasing and stock control through works orders and quality documentation to dispatch and invoicing.

The result: fewer surprises, better decisions, and production that runs the way you planned it.

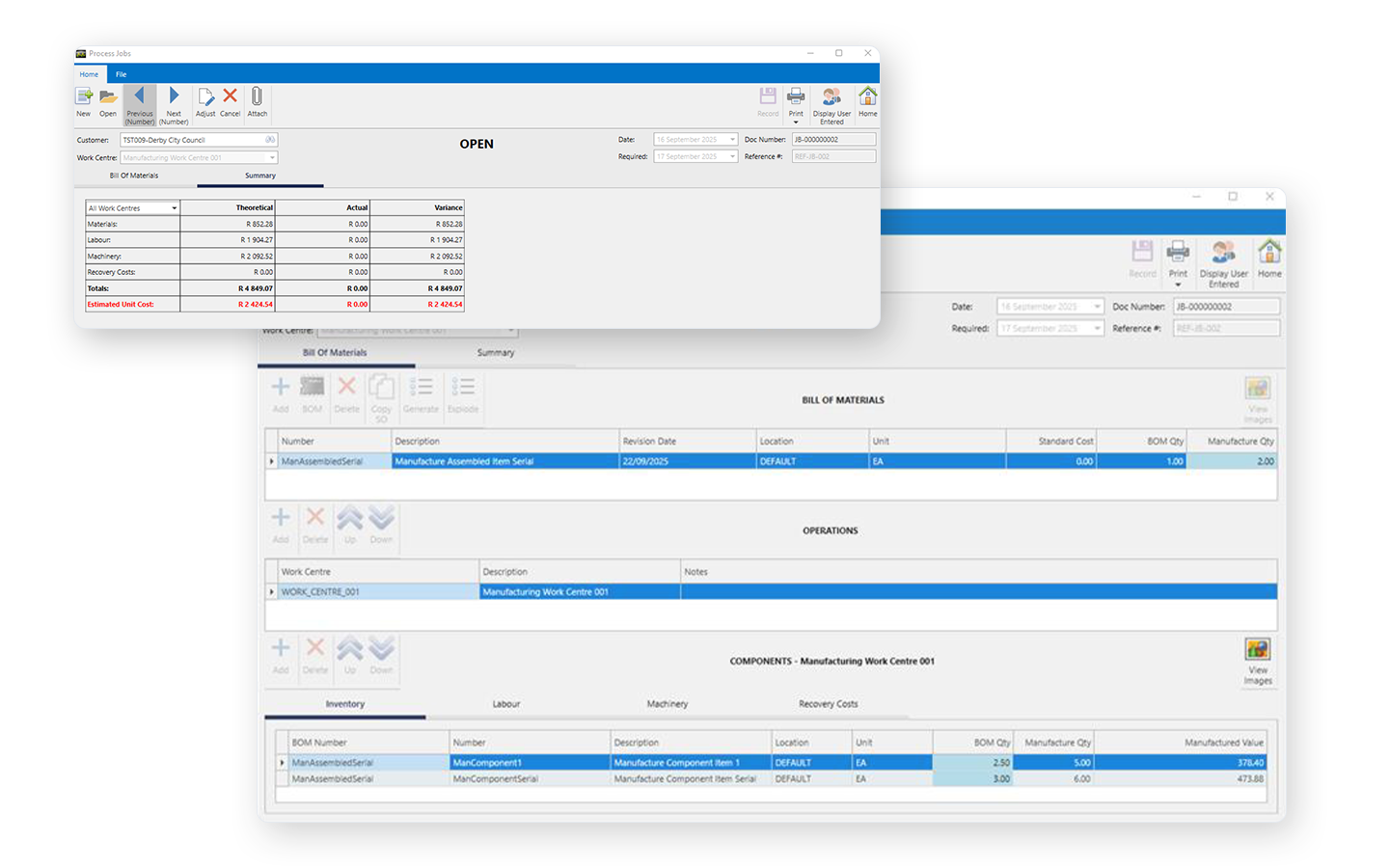

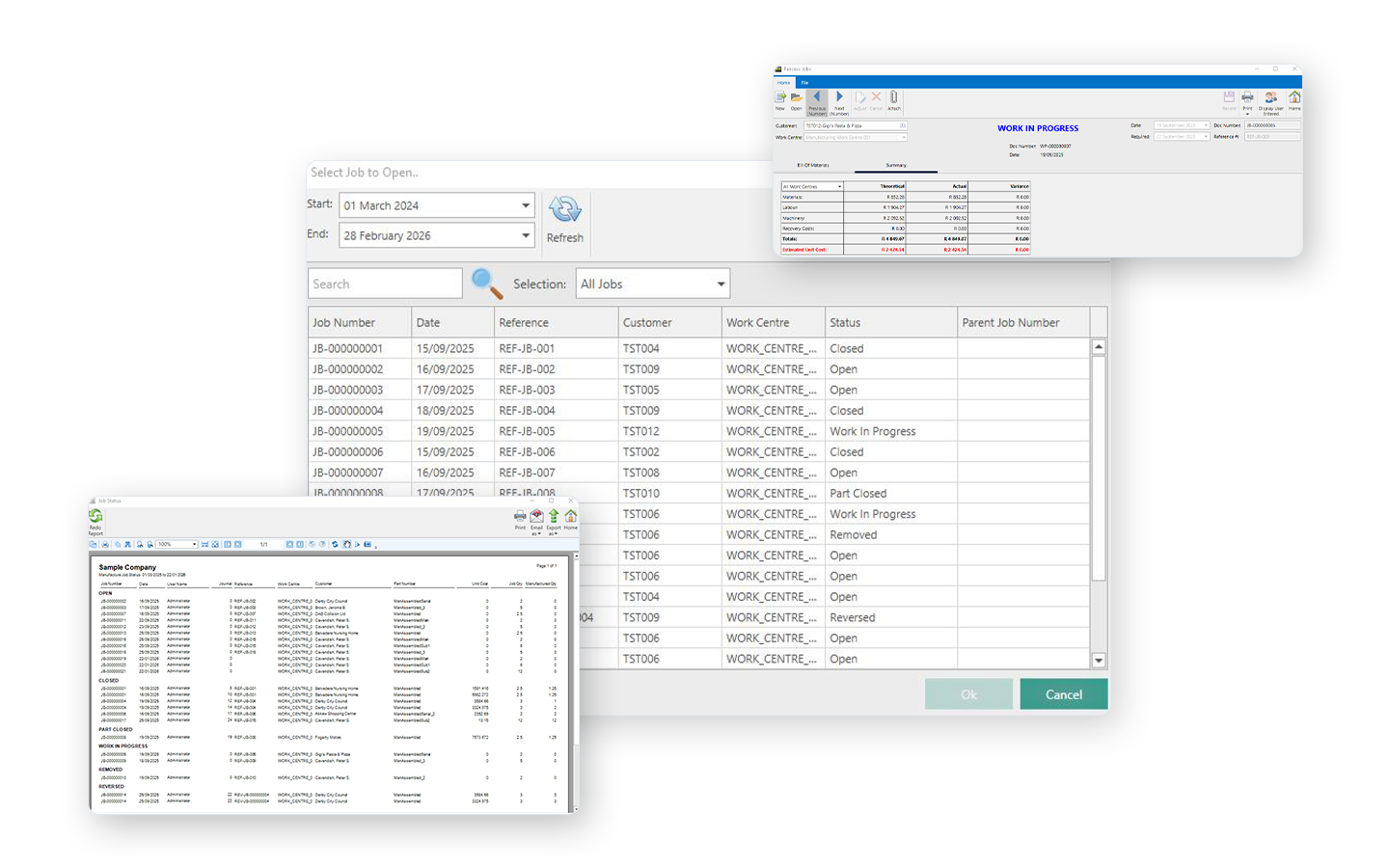

Accurate Job Profitability

Know Your True Costs Before the Invoice Goes Out

Material costs, labour time, subcontractor charges - they all eat into your margins. Klipboard Manufacturing captures actual costs against every works order, so you can compare quoted versus actual and understand true job profitability.

With real-time visibility of work-in-progress, this manufacturing management software enables informed decisions based on what’s happening on the shop floor.

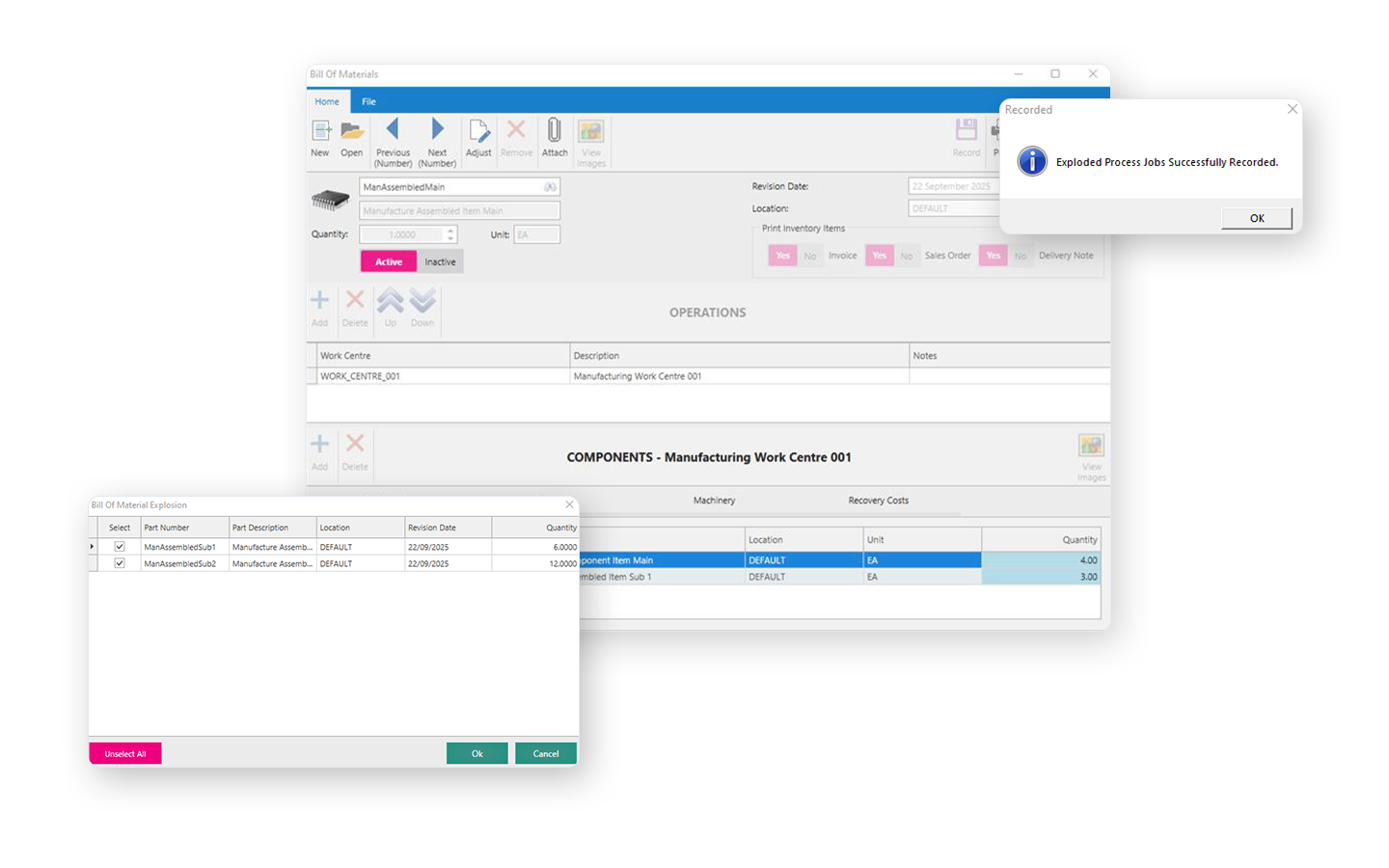

Advanced BOM Management

Multi-Level BOMs That Handle Real-World Complexity

Simple products don't need sophisticated software. But when you're managing Bills of Materials with dozens of components, handling engineering changes, or working with formulations that require precise batch control - you need tools built for that complexity.

Klipboard Manufacturing handles multi-level BOMs, tracks component allocations, manages version control, and ensures the right materials are available when production needs them.

End-to-End Works Orders

Works Orders That Track What Actually Matters

Create works orders directly from your BOMs, track production through multiple stages, and capture the data you need - material consumption, labour time, batch numbers, and quality records.

Whether you're building to order or manufacturing for stock, Klipboard delivers ERP software for Manufacturing gives you visibility of every job's status and the documentation your customers and auditors require.

Built-In Batch Traceability

Full Traceability When It Matters Most

When a customer asks where their order is, you need an answer. When quality issues arise, you need to trace back to the source. Klipboard Manufacturing provides batch and serial number control throughout your operation - from goods-in through production to dispatch.

Maintain the records required for quality standards, customer audits, and regulatory compliance without drowning in paperwork.

Inventory That Keeps Moving

Purchasing and Stock Control That Keeps Production Moving

Running out of materials stops production. Overstocking ties up cash. Klipboard Manufacturing gives you real-time visibility of stock across multiple locations, tracks supplier performance, and helps you maintain the right inventory levels for your operation.

Manage purchase orders, track deliveries, and keep production running smoothly with materials where you need them, when you need them.

Built for Your Manufacturing Sector

Every manufacturing sector has unique challenges. We've developed deep expertise across both discrete and process manufacturing, with manufacturing ERP software tailored to the specific requirements of your industry.

Trade Association Memberships

We are proud to be members of the following trade associations:

Frequently Asked Questions

What is manufacturing ERP software?

Manufacturing ERP software centralises production planning, inventory, scheduling, quality control and financials into a single system for greater operational visibility.

How does ERP software solve manufacturing problems?

ERP software improves production bottlenecks, reduces stock errors, enhances scheduling accuracy and provides real-time data for faster decision making.

How does ERP help in manufacturing?

ERP helps manufacturing by synchronising planning, resource allocation, inventory management, costing and reporting to boost efficiency and reduce waste.

What is the best ERP system for manufacturing?

The best ERP system for manufacturing integrates production scheduling, inventory control, quality management, traceability and reporting in one seamless platform.

Which ERP software is best for manufacturing?

The best ERP software for manufacturing supports multi-site operations, real-time reporting, production workflows and deep integration with shop floor systems.

Why choose ERP solutions for manufacturing?

ERP solutions for manufacturing unify systems, automate processes, improve communication and provide data insights to optimise productivity and reduce downtime.